Introduction to hookah charcoal machine:

Hookah charcoal machine is a charcoal forming machine specially used for making hookah/hookah charcoal. It presses various charcoal powders (bamboo charcoal, rice husk charcoal, fruit charcoal, etc.), natural coconut charcoal powder, etc. into round or cubic charcoal blocks under high pressure. There are 3 types of forming machines commonly used for making hookah charcoal: rotary hookah tablet press, hydraulic hookah tablet press.

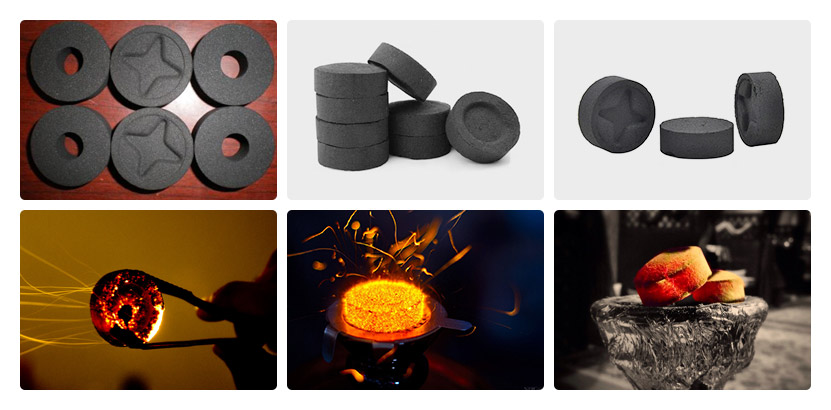

Hookah charcoal with various customized patterns and colors

Types of hookah charcoal:

Natural coconut charcoal:

Raw materials: made of carbonized coconut shells, natural and environmentally friendly.

Features: long burning time, no odor, less ash.

Suitable for hookah lovers who pursue a pure taste.

Raw materials: charcoal powder + chemical combustion aid (such as nitrate)

Quick ignition charcoal (fast burning charcoal):

Features: easy to ignite, short burning time

Suitable for convenient use.

Application of hookah charcoal:

- Fuel function: Shisha charcoal is a fuel specially used for hookah (hookah bag), mainly used to heat hookah paste or tobacco to produce smoke for inhalation.

- Replacement of ordinary charcoal: Compared with ordinary charcoal, hookah charcoal usually burns more stably, smokeless and tasteless.

Global consumer demand for environmentally friendly hookah charcoal (such as natural coconut charcoal) has increased significantly, driving the industry to transform towards low pollution and chemical additive-free. It is expected that the market share of environmentally friendly charcoal products will exceed 60% in 2030.

How to obtain hookah charcoal/raw materials for making hookah charcoal:

The raw materials for making hookah charcoal are mainly coconut shells and fruit wood, followed by agricultural waste such as sawdust, straw, corn cobs, and peanut shells.

Industrial production is mainly based on coconut shells and fruit wood, with priority given to major coconut producing countries such as Indonesia and the Philippines, using local large-scale processing plants to reduce costs; cooperate with orchards or forestry waste treatment companies to establish a raw material recycling network.

Small-scale or individual workshops can collect agricultural waste (such as peanut shells, corn cobs, sawdust, straw), combine pyrolysis furnaces with adhesives for carbonization production.

Requirements for charcoal to make high-quality hookah charcoal:

Charcoal powder for hookah charcoal must meet the core requirements of high fixed carbon, low ash content, and precise particle size. The raw materials are coconut shells and selected fruit wood. The production process must strictly control the sulfur, heavy metal content and combustion performance. Through process optimization (such as microwave carbonization) and strict testing and certification, environmentally friendly, safe and user-friendly hookah charcoal products can be produced. Read more about making high-quality charcoal.

Rotary hookah tablet press:

Rotary shisha tablet press is specially designed for making round tablet type shisha/shisha charcoal, this shisha charcoal press is very simple to operate and has very high production efficiency.

Rotary hookah tablet press

The mold of the shisha charcoal machine can be replaced, so it can process shisha charcoal briquettes of various shapes. But in order to ensure that our customers can use this charcoal machine to produce the highest quality shisha charcoal, we recommend using it to produce round-shaped shisha charcoal.

The diameter of round-shaped hookah charcoal is commonly 30 mm, 33 mm, 40 mm, etc., and it can also be customized with text, logo, logo, company phone, etc.

Round shisha charcoal with various customized patterns and colors

Technical parameters of rotary hookah charcoal machine

| Model | Power | Shape | Capacity | Rotating speed | Size | Weight |

| E.P-HSXZ | 7.5+1.1KW | Round tablet, coin, etc. | 13000~30000 pieces per hour | 10~24rpm | 1300x1300x1800mm | 2000kg |

Hydraulic hookah charcoal machine

The hydraulic hookah charcoal press is another charcoal equipment for making hookah charcoal. The hookah charcoal press is equipped with a hydraulic pump station, and customers can adjust the plastic pressure and the density of the charcoal sheet according to their requirements. It is the best-selling shisha charcoal tablet press machine on the market today, especially in the Middle East and Southeast Asia.

Hydraulic hookah charcoal machine

Features of finished products of hydraulic hookah charcoal machine:

The finished hookah charcoal pieces produced by this charcoal machine have high density, perfect shape and good appearance. Since the mold is customizable, customers can make charcoal pieces of different shapes according to their needs. Usually, cubic hookah charcoal shapes 252515mm and 252525mm are the most popular in the market.